How

Dynamico

Works

Dynamico gets to work in your engine straight away. After adding it to the fuel, this novel and cutting-edge fuel additive technology will start breaking down the deposits coating the fuel delivery system. Within one tank, the injector nozzles will be cleaned. Continued use of Dynamico stops the build-up of future deposits.

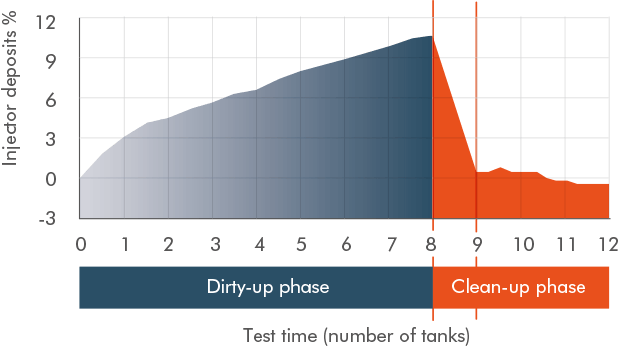

The Dynamico clean-up time

Dirty-up phase

GDi vehicles can suffer from injector fouling without the use of specific GDi additive technology and unexpected contaminants present. This negatively affects the injector system by forming deposits. The engine will have to deliver increasing amounts of fuel to maintain engine power.

Clean-up phase

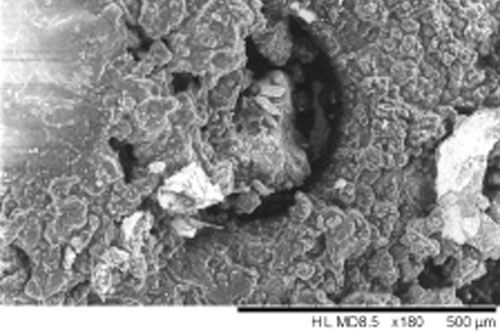

Dynamico delivers 100% recovery of injector fouling within one tank of fuel. That's all the time it takes to return precision components to an 'as new' condition. By removing the deposits and controlling future deposit formation, Dynamico makes sure an engine will always perform as the manufacturer originally intended, over the whole life of a vehicle.

nozzle

nozzle

after additive

Finding solutions for the real world

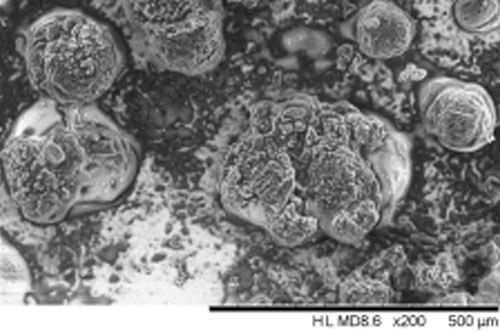

Using our experience as market leaders in fuel additive technology, our world class team set out to solve the problem of how to control injector deposits in the latest GDi engines. Injector fouling negatively affects the efficiency and emissions benefits of this engine technology. This impact has become apparent in new vehicles using fuel which has not been treated with specific GDi additive technology. Deposit build up in the injector system seriously affects the performance of a GDi engine and can result in fuel injector failure in extreme cases.

The solution is to use specifically designed deposit control additives to remove injector deposits and prevent injector fouling, dramatically reducing particle emissions and increasing fuel efficiency. This also preserves engine power and maintains optimum reliability. New industry tests carried out in our state-of-the-art laboratories using the industry standard Volkswagen EA 111 engine shows Dynamico delivers best-in-class performance when clean-up recovery is measured in a real-world driving simulation.

We have developed a new generation of deposit control additives for GDi engines that not only allows control of injector deposits and their removal, but also provides emissions benefits. Our patented technology is proven to significantly reduce particulate emissions which are harmful to human health.

How Dynamico delivers on

particle emissions

To keep emissions under control, a GDi engine must run at optimal efficiency. However, using fuel without specific GDi additive technology, deposits can form in fuel injectors which quickly disrupts critical engine efficiency. This impacts vehicle performance which in turn affects emissions. By removing deposits with Dynamico it is possible to significantly reduce particulate emissions.

existing fuel system deposits

fuel system

fouling

fuel

efficiency

engine

power

Complete performance for all gasoline engines

Dynamico provides performance not just in the newest generation of gasoline engine technology. Our fuel additive technology is as effective in Port Fuel Injection (PFI) engines. This engine type delivers fuel via the inlet manifold and suffers from deposition on the inlet valves before the combustion zone.

Dynamico not only prevents the formation of inlet valve deposits (IVD) but also offers outstanding cleaning power to remove these deposits.

By ensuring that the fuel system is free from deposits it will maintain the efficiency and performance of the engine according to the way it was designed.